Geodetic deformation monitoring

_________________________________________________________________________

Everything in our world is in a state of relative movement. Soil drift near the facility under observation, a complicated design proposal and heavy mass, the facility location in a highly earthquake-prone region; all this leads to deformation processes that can be both permissible and critical (Figure1).

Figure 1 Detection of detrimental deformations |

AlmatyGeoCenter LLP is pleased to offer today a wide scope of deformation monitoring services for subsoil users and construction companies. Among these are the following:

- Obtaining information on facililties deformations caused by temperature fluctuation, wind effect and change in loads.

- Detection of the deformation propagation direction. Determination of verticality deviations and torsion of structures.

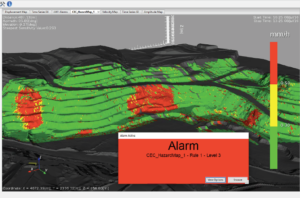

- Data analysis and interpretation aimed at detecting detrimental deformations in order to prevent further damage to the facility or avert a disaster (Figure 2). Data analysis enables to determine the change in the spatial position of key points of the facility in time, as well as to prevent overload on the facility and streamline the operational work.

Figure 2 Prevention of damage to the facility |

Systematic mine surveying and geodetic observations arranged enable to avert disasters, minimize losses and avoid casualties – this is a key part of risk management, which is used for monitoring of complicated engineering facilities. The facility monitoring is possible both during the facility construction and during its subsequent operation.

In today’s world, the number of oil and gas fields and open pits is increasing (Figure 3). Increasingly complicated design of engineering facilities raises, surely, the risk of man-made emergencies. It shall be also borne in mind that many facilities are located in earthquake-prone areas.

Figure 3 Geodynamic observations at borrow pits |

What facilities are usually subject to geodynamic observations? Bridge crossings, high-rise buildings, borrow pits, natural landscapes (earthfalls and mudflows), tunnels and mines, railway tracks, dams and dykes.

A large number of engineering facilities are designed with disregard for today’s requirements for seismic impact. Structures ageing and accumulation of deformations during the long-term operation lead to changes in the physical and mechanical properties of materials, of which the facilities are constructed, and bedding soils. Any engineering facility is also characterized by the so-called “self-induced vibrations”, the frequency of which depends on the structural design features of the members of the facility, the materials used and a number of other factors.

Deformation monitoring enables to record any deviations from the design values even the most insignificant ones (not to mention serious ones caused, for example, by natural disasters). Continuous monitoring of deformation processes contributes to before-the-fact prevention of resulting risks and taking the necessary measures to prevent accidents. Continuous deformation monitoring is an efficient investment protection instrument.